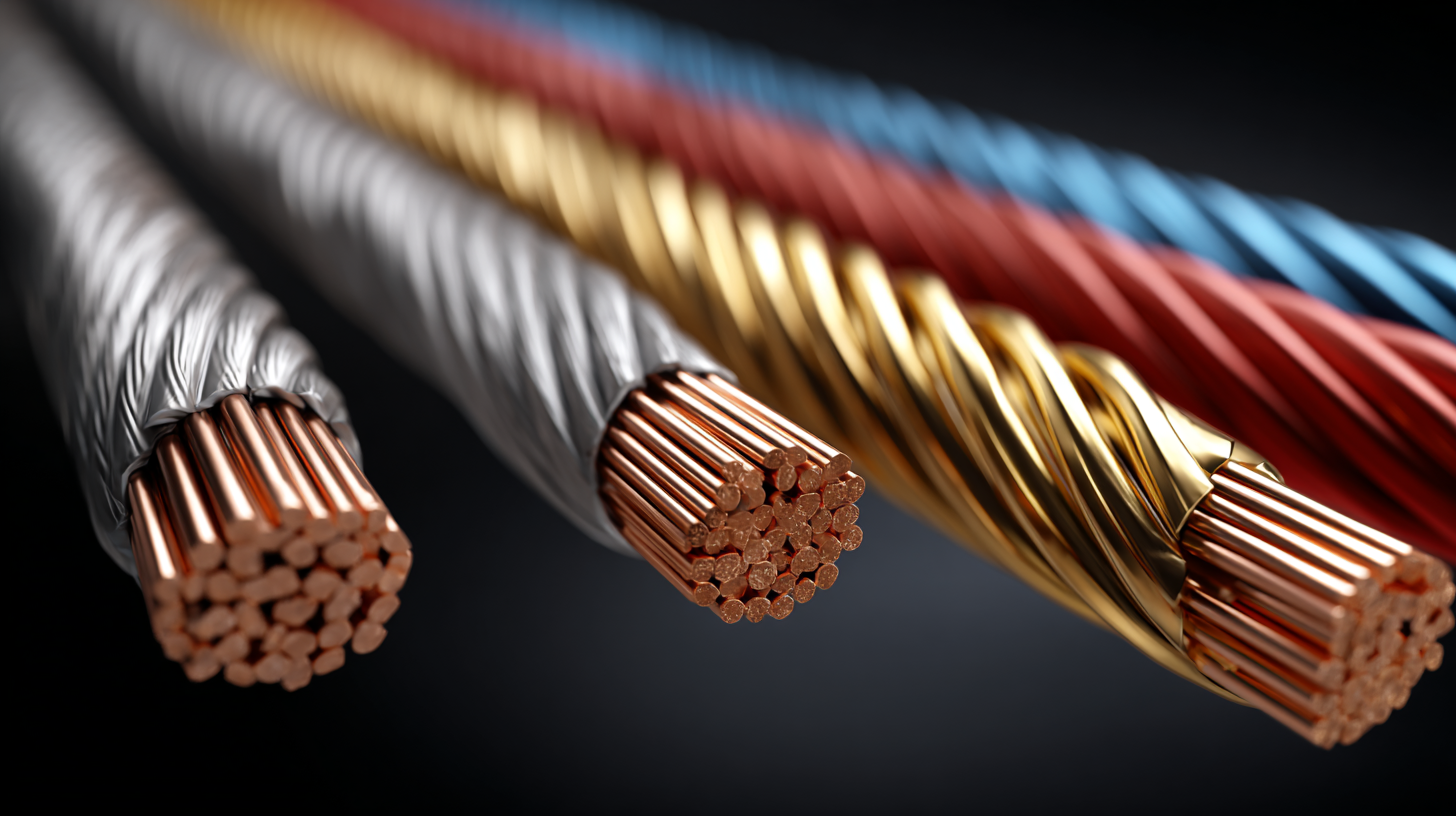

In today's technologically driven world, the reliability and lifespan of electrical cables are paramount to ensuring efficient and safe operations across various industries. According to a report by Allied Market Research, the global market for electrical cables is projected to reach $210 billion by 2027, reflecting a growing demand driven by extensive infrastructural development and advancements in renewable energy systems.

However, the longevity of electrical cables is highly influenced by factors such as material quality, environmental conditions, and installation practices. A study by the Institute of Electrical and Electronics Engineers (IEEE) indicates that improper installation can reduce cable lifespan by up to 50%, highlighting the need for best practices in cable management.

This article aims to elucidate the critical aspects of electrical cable lifespan and reliability, providing insights into how to effectively select, install, and maintain these essential components in modern applications.

However, the longevity of electrical cables is highly influenced by factors such as material quality, environmental conditions, and installation practices. A study by the Institute of Electrical and Electronics Engineers (IEEE) indicates that improper installation can reduce cable lifespan by up to 50%, highlighting the need for best practices in cable management.

This article aims to elucidate the critical aspects of electrical cable lifespan and reliability, providing insights into how to effectively select, install, and maintain these essential components in modern applications.

The lifespan of electrical cables in modern installations is significantly influenced by several critical factors. According to a report by the International Electrotechnical Commission (IEC), cable insulation materials can vary widely in durability, directly impacting performance and longevity. For instance, cross-linked polyethylene (XLPE) cables are noted for their excellent thermal and mechanical properties, often extending their operational life beyond 50 years under optimal conditions. In contrast, thermoplastic materials generally exhibit a shorter lifespan, often less than 25 years, when subjected to the same environmental stressors.

Environmental factors also play a crucial role in determining the lifespan of electrical cables. A study published by the Institute of Electrical and Electronics Engineers (IEEE) highlighted that exposure to moisture, extreme temperatures, and UV radiation can lead to premature aging and degradation of cable materials. For example, cables installed in coastal areas where saltwater is prevalent may experience accelerated corrosion, shortening their lifespan by as much as 30%. Additionally, improper installation techniques, such as inadequate bending radius and excessive tension during pulling, can further compromise the integrity of the cables, leading to failures that could have been prevented.

This chart analyzes the average lifespan of various types of electrical cables used in modern applications, as well as the impact of environmental factors on their reliability.

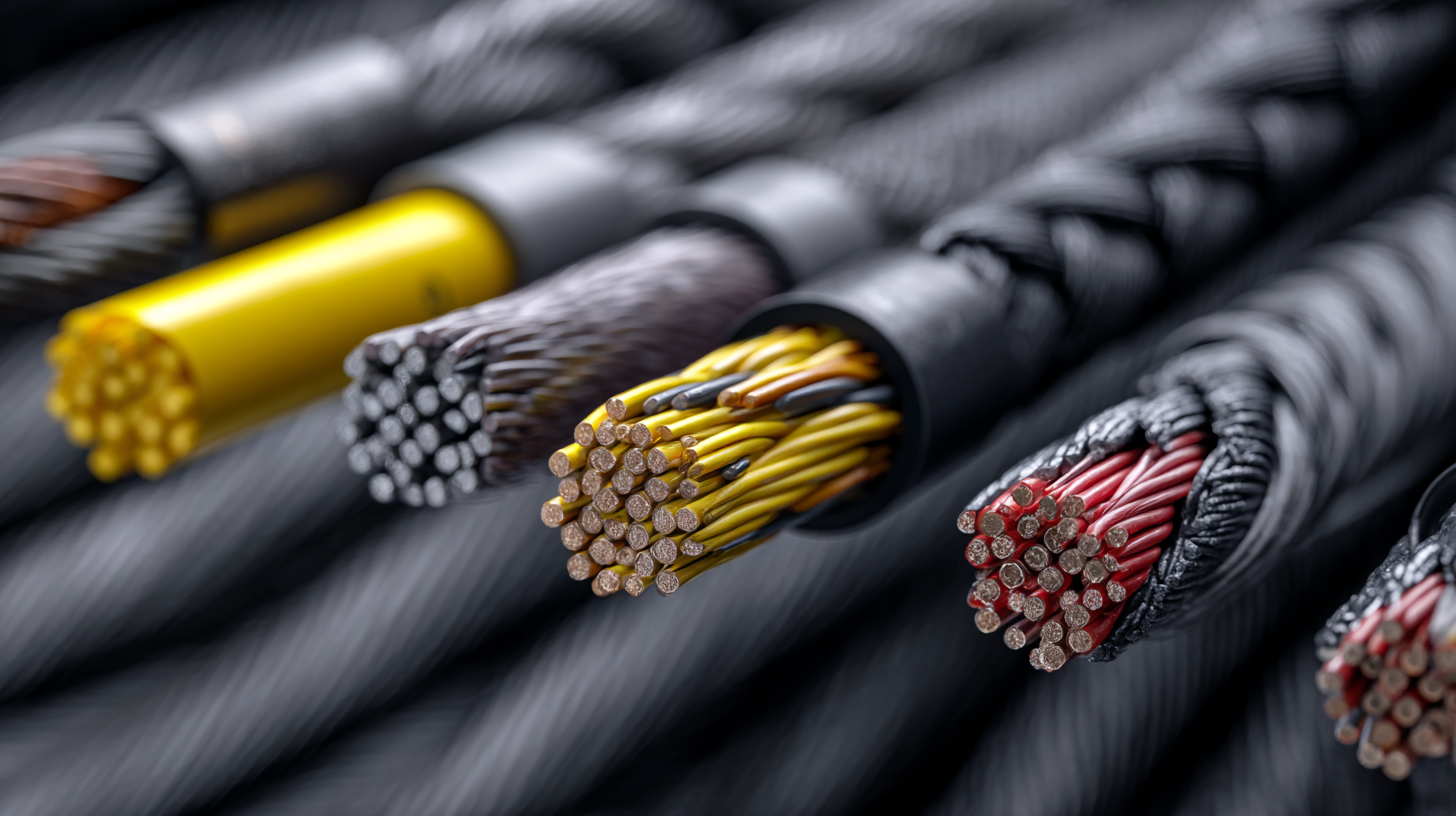

Electrical cables play a crucial role in modern applications, but their lifespan can often be compromised by various factors. Common causes of electrical cable failure include

wear and tear due to mechanical stress, exposure to moisture, and thermal overload.

Mechanical stress can occur during installation or as a result of environmental conditions, leading to physical damage over time. Additionally, moisture can lead to corrosion and insulation breakdown, effectively diminishing the cable's performance and reliability.

To prevent these failures, regular inspection and maintenance of electrical cables are essential. Ensuring proper installation techniques can mitigate mechanical damage, while using moisture-resistant materials can protect against environmental hazards. Implementing thermal management strategies, such as avoiding cable congestion and ensuring proper ventilation, can prevent overheating. By addressing these common issues proactively, the lifespan and reliability of electrical cables can be significantly enhanced, ensuring they meet the demands of modern applications.

In modern electrical applications, the reliability of cables is paramount, governed by stringent industry standards that ensure performance and safety. Testing processes play a crucial role in determining the lifespan and durability of electrical cables. Organizations such as the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have established rigorous testing protocols to assess various cable attributes, including thermal performance, mechanical stress resistance, and environmental durability. According to a 2020 IEC report, cables that meet these standards can have a operational lifespan exceeding 30 years under optimal conditions.

Furthermore, the National Electrical Manufacturers Association (NEMA) emphasizes the importance of continuous real-world testing. Their studies indicate that cables exposed to harsh environments, such as extreme temperatures or chemical exposure, may experience a significant decrease in reliability. For instance, cables tested at elevated temperatures showed a degradation rate of up to 20% over 10 years, underlining the need for comprehensive testing to guarantee cable performance in specific applications. As technology advances, ongoing updates to these testing processes will be vital to ensure that cables meet the evolving demands of modern electrical systems.

| Cable Type | Average Lifespan (Years) | Typical Applications | Testing Standards | Failure Rate (%) |

|---|---|---|---|---|

| Low Voltage Cable | 30 | Commercial Buildings | UL 83, IEC 60502 | 1.2 |

| Medium Voltage Cable | 25 | Industrial Plants | IEEE 400, IEC 60502-2 | 0.8 |

| High Voltage Cable | 40 | Power Transmission | IEC 60840, ASTM B903 | 0.5 |

| Fiber Optic Cable | 20 | Telecommunications | TIA/EIA 568, ISO/IEC 11801 | 0.3 |

| Coaxial Cable | 15 | Broadcasting, Internet | MIL-PRF-39012 | 1.0 |

The growing focus on renewable energy sources, such as solar, wind, and hydropower, is significantly influencing the wires and cables market, particularly in the context of material selection for electrical cable production. When comparing PVC and XLPE cables, the durability and long-term reliability of XLPE make it a favorable choice for modern applications, especially in sustainable infrastructure. XLPE's resistance to environmental stressors, such as moisture and temperature fluctuations, enhances the lifespan of electrical systems, which is crucial for renewable energy installations.

In terms of cost, while XLPE cables may initially be more expensive than PVC, their long-lasting durability leads to lower maintenance and replacement costs over time. As electric utilities seek solutions to minimize service interruptions and enhance system reliability, the demand for high-performance materials like XLPE is expected to grow. Furthermore, emerging developments, such as water tree retardant TR-XLPE, promise even greater reliability in medium voltage power cables, reinforcing the argument for XLPE as a superior choice in the dynamic landscape of electrical cable applications.

Maintaining the performance of electrical cables over time is crucial to ensure safety, efficiency, and longevity in modern applications. One of the best practices is to conduct regular inspections. Visual checks can help identify signs of wear, such as cracks in insulation or fraying of wires. Additionally, thermographic inspections can detect overheating connections, preventing potential failures before they occur. It's essential to create a routine maintenance schedule that includes these inspections, thereby addressing issues promptly.

Another key aspect of cable performance maintenance is proper installation and handling. Ensuring that cables are installed according to manufacturer specifications prevents undue stress and damage. Employing protective measures, such as conduit and cable covers, can shield cables from environmental factors and mechanical wear. Moreover, maintaining an organized and clutter-free workspace reduces the risk of accidental damage that can compromise the integrity of the cables. By adopting these best practices, users can significantly enhance the reliability and lifespan of electrical cables, ensuring smooth operation in various applications.